Steering Rack

The steering rack for the Baja SAE car was a project that gave me opportunity to improve on an existing design as well as iterate on my own design. I was the responsible engineer for this part for both the 2022 and 2023 seasons so this critical component saw huge improvements. I improved the assembly of this part by using a thermal shrink fit instead of a press fit to ensure proper alignment of the full assembly once it is mounted to the car. I also used the ANSI fit tolerancing system to ensure correct fitment of the many in house manufactured components.

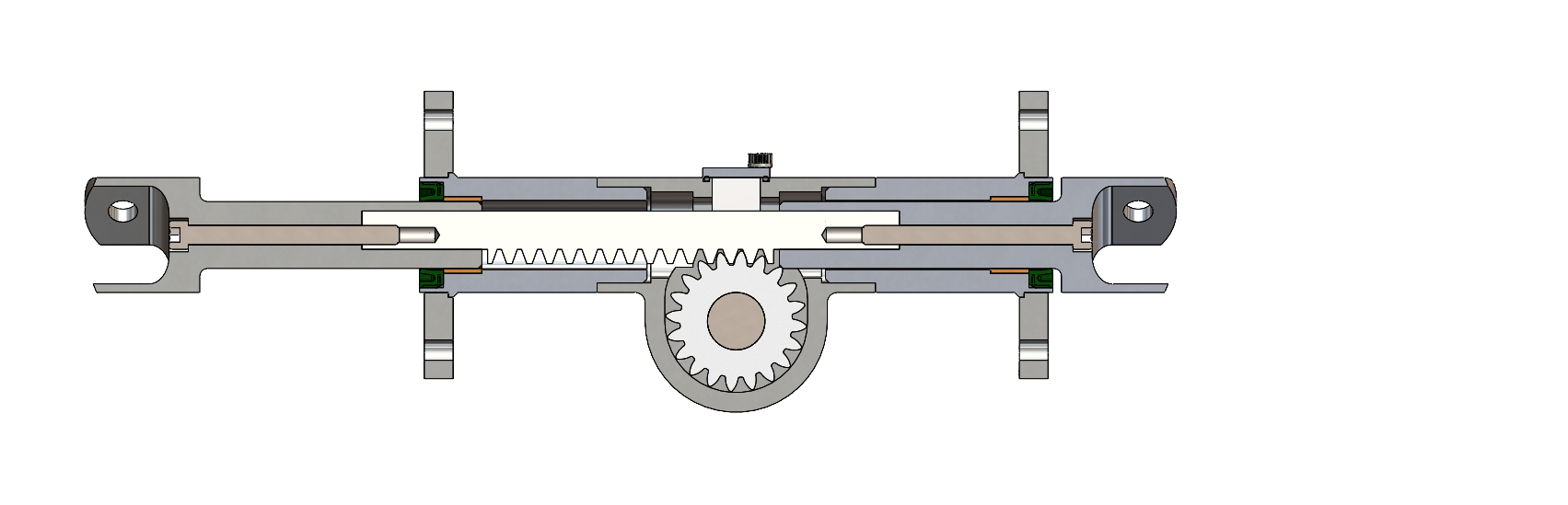

The body of the rack is custom made from 6061 aluminum. The steering clevises are made from 7075. The gear rack is an off the shelf gear rack that we machine down to reduce size and weight. The steering pinion is a custom machined 8620 blank which was custom hobbed to ensure minimal backlash.

2019 Steering Rack Design I inherited

In 2022, I focused on issues the team had with manufacturing, using, and performing maintenance on the steering racks designed and made in 2017 and 2019. The most prominent issue was installation and assembly difficulty, high steering effort, and dirt ingress. For the 2022 rack I used better off the shelf seals for the steering clevises and the pinion shaft. The manufacturability was also improved by dimensioning and tolerancing all component interactions using the ANSI fit tolerancing system. I also reduced the rack mounting feet to one part per side instead of three, and I added orientation control features to the rack arms and rack feet.

2022 Steering Rack I designed

My 2022 rack design was put to the test across 3 competitions including a cumulative 12 hours of endurance racing in dusty and muddy environments. The assembly difficulty, steering effort, and sealing were much improved from previous designs.

The ANSI fits helped assembly of slip fits as well as the main shrink fit for the rack body. One issue that came up was the press fit for the steering clevis bushing. This bushing was pressed into the rack arm using an interference fit, but once the bushing was pressed, the sliding fit for the steering clevis disappeared. For the 2022 rack, the bushing was post-machined in a lathe, but for future years the tolerance was updated to remove the extra step.

Steering effort was reduced by ensuring an appropriate fit and datum strategy. The sliding fit tolerance on the steering clevises combined with a datum strategy to keep the rack arms and pinion housing axes coaxial reduced steering effort dramatically. Besides the initial steering effort improvement, the steering effort stayed low due to the sealing improvments. In previous iterations, dirt would mix with the grease packed within the rack to greatly increase the resistance in the gear mesh. The improved sealing helped keep the grease clean throughout the lifecycle of the rack.

2023 Rack Design

For 2023 I built on the improvements I made in 2022 to solidify the design further. Some of the immediately evident changes include the face sealing pinion cap and the smaller Pinion Housing. I also shrunk the rack feet because they were overbuilt in 2022. I also made the rack feet identical to reduce the number of unique parts. The 2023 steering rack performed admirably in both official competitions in Oshkosh, WI and Washougal, WA.